Air Nailers 101

Probably the biggest revolution in the past ten years is the affordability and availability of pneumatic nailers.

Bit of HIstory

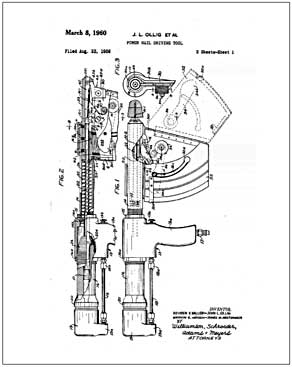

The first pneumatic nailer was invented in John Ollig's garage in Winsted, MN, he and several friends came up with the idea over a beer at the local Legion. Ollig, Reuben Miller and Marvin Hirsch all veterans of World War II had first hand knowledge of how machine guns worked so they set about designing a pneumatic nailer based on one.

Once the a workable model was developed they along with the owner of the local lumberyard, James Westerholm patented the idea along with the concept of multiple nail clips in 1960.

Port-A-Matic Tools was formed to manufacture it rather than licencing the patents to an existing tool company. Unfortunately they did not have the finances to carry on, the company was eventually foreclosed by the bank and the patents were sold at auction to Bostich.

The Basics

Pneumatic nailers work by compressed air propelling a piston to drive the fastener. Like ordinary nails driven with a hammer the fasteners come in many sizes, and styles. There are many lengths, gauges and styles of heads to choose from, unfortunately there is no universal gun, you must choose one for the type of fastener you will be using.

There are two types of safety interlocks, one requires that the nose of the gun be pressed to the surface before the trigger will work, the other known as "bump firing" fires when you hold the trigger and press the nose to the surface.

Since nailers only use a short burst of air to drive the fastener almost any compressor will be adequate. There is a wide variety of small airless compressors on the market today, many of them are very noisy, fine on a construction site maybe but not when used in a shop.

When selecting a type of gun there are several things to look for.

1. All nailers occasionally jam, one with a flip latch is more convenient to use than having to remove screws.

2. Get the lightest gun that will do the job, some can weigh up to nine pounds and get heavy as the day goes on.

3. Adjustable exhaust ports to direct the exhaust away from your face are nice when working in cramped quarters.

4. Holding strength of varies, brad nailers and pin nailers make a small hole and are fine for trim or if used with glue but do not have the holding strength of finishing or framing nailers.

5. Some models have dials to adjust the depth the fastener is driven into the material, otherwise the regulator on the compressor will have to be set, this is not critical if you only have one nailer but can be a nuisance if you are using multiple guns. Another work around is to attach a small regulator to the gun.

6. For trim and other finish work you may want a "no mar" rubber protector on the tip to prevent marks on the material.

The Types Available

Framing

These are the big boys, they drive nails up to 4" long, used in rough construction for maximum strength. The fasteners come with a clipped or full round style head. There are two configurations of magazines, "coil" or "stick".

Finishing

Finishing nailers drive fasteners up to 2 1/2" long and are available in 15 or 16 gauge. They are used finish carpentry, such as securing door casings, exterior trim and cabinet construction.

Brad Nailers

Brad nailers drive smaller 18 gauge finishing nails up to 2" long. They are used for trim work and in the shop to hold glued material in place until the glue sets. These are the style most home woodworkers start out with.

Pin Nailers

Pin nailers drive 21 or 23 gauge headless fasteners, used in the shop to hold material in place until glue sets and for small mouldings. They leave small holes that are often no longer visible after sanding. Safety

Nailers demand respect and should always be used with caution, wear eye protection. Nails may ricochet if they hit a knot or dense material. Remember that bump fire guns will shoot into a foot as easily as a board.