Home Built Router Power Feed

| I

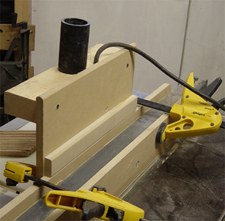

had to round over two corners on 600 lineal feet of 1/2 inch thick by 1

1/4 inch wide MDF strips, I found that when I had hold downs set up for

both the side and the top there wasn't much room for a push stick. The

fact that I knew this job would be coming up again and my hands don't

like a lot of repitive stress anymore prompted me to find another

solution.

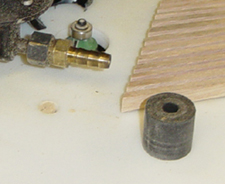

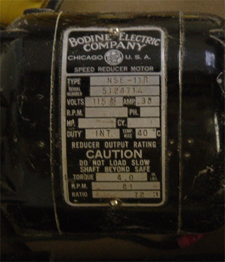

Years ago I picked up a junk motor with a reduction gear from a printing shop, I took a look at it and guessed that It might just do the job. I pushed a rubber center from a drum sanding kit on to the shaft and tested the speed it would drive a strip of wood across the top my workbench, it seemed about right.

The strips have to be pushed by hand past the router bit into the feed roll. Over all it worked very well, it got the job done, best of all I just had to feed and catch the strips, no stress, no aching hands at the end of the day. |